Friction across wire pulleys causes their grooves to be worn down over time.

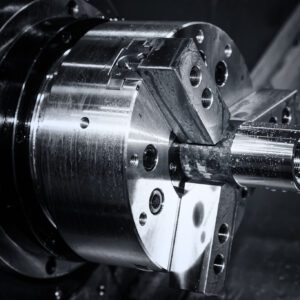

Lewis & Raby refurbishes used wire pulleys by machining off the original pulley wall and re-machining a new aluminium ‘tyre’ which is bolted to the original.

The replacement grooves are cut to precision to ensure smooth operation of the pulley.

The pulley is finished by a process of hard anodising which provides increased corrosion and wear resistance.

Please contact our engineering team for more details.